SIEMENS SERVO MOTOR DRIVES IN INDIA

Leading distributor and dealer of Servo Motor Drives from Siemens in India

Overview

Automation Direct India is a leading dealer and distributor of Siemens Servo Motor Drives in India. We distribute Siemens Servo Motor Drives in Chennai, Bangalore, Pune, Mumbai, Ahmedabad, Hyderabad and Delhi.

Function of a Servo Drive

A servo drive, sometimes referred to as an amplifier, takes the command signal for position, speed or torque requirement and adjusts the voltage and/or current applied to the servo motor using closed loop control.

Components of a Servo System

A servo drive is an integral part of a servo system which also includes the controller, motor and feedback device. Communication to and from controllers and other devices can be via a simple digital and analogue i/o or digital fieldbus communication, such as EtherCAT, CANopen and many other industry standard protocols.

Design and Operation

Our servo drives are designed to be cost-effective, fast, and easy to use while operating complex applications without specific drive know-how or additional engineering tools. The drives concentrate on both hardware and functionality ensuring ruggedness and reduced investment cost. The operation allows highly dynamic movement of minimal loads and ultra-precise movement of medium and high loads.

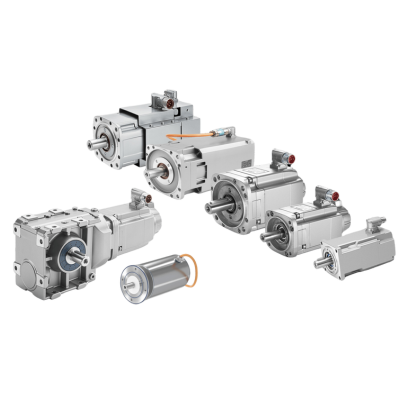

SIEMENS SERVO MOTOR DRIVES

SIEMENS SERVO MOTOR DRIVES – SIMATIC MICRO-DRIVE PDC

SIMATIC MICRO-DRIVE is the drive system in the safety extra-low voltage range from 24 V to 48 V. Composed of the SIMATIC MICRO-DRIVE, flexibly usable motors and connecting cables of selected product partner, the SIEMENS product portfolio for extra low voltage is expanded. Compatible controllers from the SIMATIC portfolios complement the motion control functionalities of this future-proof solution.

SIMATIC MICRO-DRIVE PDC (ProfiDrive-Control) standalone servo drive system is versatile, seamless, and safe for applications in the extra-low voltage range from 24 V to 48 V. It covers a wide range of applications, including precise positioning, shuttles for storage and retrieval machines and storage systems, automated guided vehicles (AGVs), and medical technology.

Highlights

SIEMENS SERVO MOTOR DRIVES – SINAMICS V70

The SINAMICS V70 servo converter is designed for controlling standard applications of turning and milling machines. It enables precision and efficiency of the machines through bus communication with the CNC control 808D ADVANCED, 3-fold overload capability and the 20-bit absolute encoder with high resolution in the feed motors SIMOTICS S-1FL6 and the main spindle motors SIMOTICS M-1PH1.

Highlights

SIEMENS SERVO MOTOR DRIVES – SINAMICS S210

The SINAMICS S210 system comprises a servo converter and a servomotor – and mainly addresses solutions demanding a high dynamic performance in the power range from 50 W to 7 kW. Machine safety functions are integrated. The connection to a higher controller is established via PROFINET IRT communication, fast commissioning via the TIA Portal or the integrated web server and One Button Tuning.